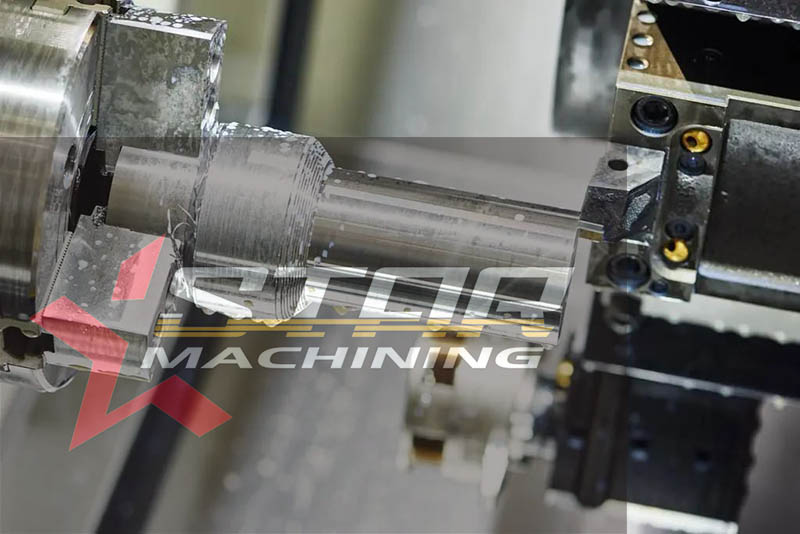

Precision machining is a process that deals with formation of the products that we use in our daily life that may consist of some small objects or large objects. Precision machining is the one that is carried out in close tolerance. It develops the products with high precision and accuracy, which will required the CNC, Abrasive machining, Planarization (CMP etc.), Micromachining, EDM, Energy beam machining, Injection molding and different machines of hybrid and high technology and it is helpful in making precisely even the complicated design components.

Now-a-days, as the technology is getting more and more advanced so only precision machining will not help us. Along with this, there are so many factors that one must work upon to become a respectable precision machining manufacturer. We are living in an era of accelerated world-changing, where innovation in every field, exponential increase in the use of modern technologies has changes the scenario. Innovation is solving the complex problems by the proper emphasis on the key features.

Start adopting the advance technology to improve the product performance by working with accuracy, reliability, improving product’s life, increasing manufacturability with animation.

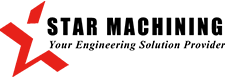

The most important part is design and development. In the design process evaluate the best possible resources that are available. Study the problem carefully and make sure to understand the needs of what all should be done and what are the constraints. Thereby use high accuracy design software’s and stimulation software that will help in the production of complex and 3-D design. The manufacturing part should be the blueprint of the design, and should satisfy the standard requirement this can be called as precision machining.

Analyse the constraints for particular project such as the time duration of the project, how much man power will be required, checkout the resources available. These all the above factors will help you to work efficiently and to make your machining service precise.

Try to make all possible test on prototype in development process, this will verify the design. Use rapid prototyping.

Precision machining will require the high skilled machinist, the one who has the knowledge of each and every small tools and objects. He is the only one that will assures us that the manufactured product is designed according to the standard requirement.

For precision machining high accuracy design methodology is important. Consider all the factors and try to improve each of these factors in design and development phase. Implementation of technology is necessary, analysis the capabilities and proper planning is required for every individual job.

Star machining is continuously working on the same. Star machining is expert in design and development that works on high accuracy measurement process, hybrid machines for operations and serves the quality assurance to their customers.