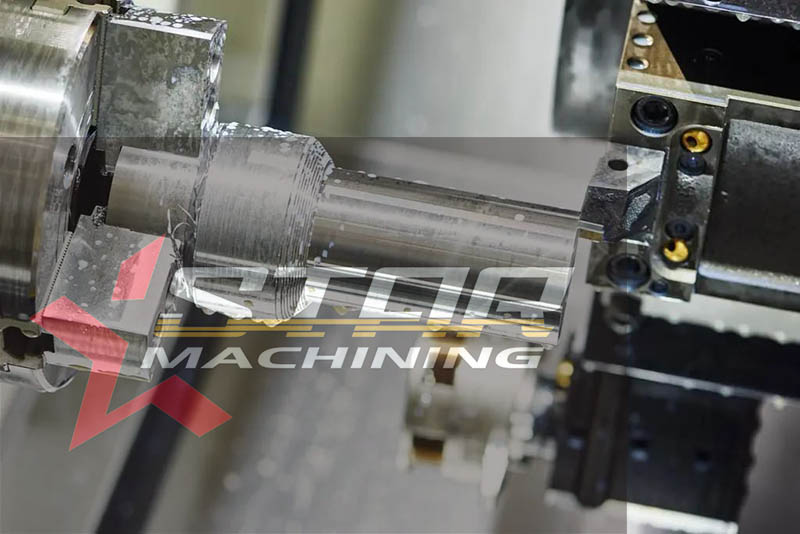

CNC grinding services are used by CNC machines to remove material from a metallic workpiece using a spinning grinding wheel. Workpieces that require hard, fine machining are best suited for use with grinding machines. Due to the extremely high surface quality that may be produced, grinding machines are usually used as a finishing procedure in modern industry with good grinding capabilities .

What are the advantages of CNC grinding processing

- The CNC grinding makes the machined parts with high precision and stable quality

The positioning accuracy and repeat positioning accuracy of the CNC grinding machine are very high, and it is easier to ensure the consistency of a batch of parts. As long as the process design and program of the CNC grinding machine are correct and reasonable, coupled with careful operation, the parts can be guaranteed to obtain high machining accuracy. It is convenient to carry out quality control on the processing process of CNC grinding machine.

- The CNC grinding machine has a high degree of automation, which can reduce the physical labor intensity of the operator

The machining process of the CNC grinding machine is automatically completed according to the input program. The operator only needs to start the tool setting, load and unload the workpiece on the EDM machine, and change the tool. During the machining process, he mainly observes and supervises the operation of the machine tool.

- The dimension marking of CNC grinding machine should conform to the characteristics of grinding machine processing

In the CNC programming of CNC grinding machines, the size and position of all points, lines, and surfaces are based on the programming origin. Therefore, the coordinate dimensions are directly given on the part drawing, or the dimensions are quoted on the same basis as much as possible.

- Uniform geometry type or size

The shape and inner cavity of CNC grinding machine parts adopt a uniform geometric type or size, which can reduce the number of tool changes, and it is also possible to use control programs or special programs for CNC grinding machines to shorten the program length. The shape of the part is as symmetrical as possible, which is convenient for programming by using the mirror processing function of the CNC grinding machine to save programming time.

Basical Types of CNC grinding machines

Grinding is a finishing operation which is to gives the required accuarcy and precision by removing the extra material. Here we list some common types of CNC grinding machines below:

- Cylindrical grinder: it is a common type of base series, mainly used for grinding cylindrical and conical surface grinder.

When the workpiece is hardened or when the need for high accuracy and excellent finish arises, they take the place of the lathe. The grinding wheel, which rotates considerably more quickly in the opposite direction, comes into contact with the part as it circles. While in contact with the grinding wheel, the workpiece and table revolve to remove material.

- Internal grinding machine: It is the basic type of common type, mainly used for grinding cylindrical and conical inner surfaces. In addition, there are grinding machines with both internal and external cylindrical grinding.

- Centerless grinding machine: The workpiece is clamped centerlessly, generally supported between the guide wheel and the bracket, and the guide wheel drives the workpiece to rotate. It is mainly used for grinding cylindrical surfaces. For example, bearing shaft support, etc.

- Surface grinder: A grinder mainly used for grinding the plane of the workpiece.

- The hand grinder is suitable for the processing of small-sized and high-precision workpieces, and can process various special-shaped workpieces including arc surfaces, planes, and grooves.

- The large water mill is suitable for the processing of larger workpieces, and the processing accuracy is not high, which is different from the hand grinder.

- Belt Grinder: A grinding machine that grinds with a fast-moving abrasive belt.

- Guide rail grinding machine: a grinding machine mainly used for grinding the guide rail surface of machine tools. 7. Multi-purpose grinding machine: a grinding machine used for grinding cylindrical, conical inner and outer surfaces or planes, and can grind various workpieces with follow-up devices and accessories

- Special grinding machine: a special machine tool for grinding certain types of parts. According to its processing objects, it can be divided into: spline shaft grinder, crankshaft grinder, cam grinder, gear grinder, thread grinder, curve grinder, etc.

The grinding machine is widely used in small and large industries to grind any workpiece or job. If you need to use CNC grinding services in your project, please feel free to contact us for inquiries. Thanks!