In the present era, the biggest challenge for any manufacturing company is to manufacture the goods of reduced weight. Especially for an Automobile industry weight reduction is the most important challenge as many of the key factors are considered such as fuel efficiency, performance, safety, durability, and cost. These all are the challenges that are kept under consideration. In today’s world every breakthrough innovation are is based on technology driven orientation. In such a period, the heavy components are replaced by the aluminum die casted products, i.e. from the alloy wheels to engine components.

Through this article Star Machining Technology Co. Ltd., has conveyed the information about the importance and advanced features of Die Casting Aluminum parts and how rapidly these parts are replacing the heavy components with their increasing demands in market.

Following are the advantages of replacing the heavy components with aluminum. It reduces the amount of generated fuel and maintenance costs thereby increasing durability.

- Saving weight results in saving money: – When we are talking about saving weight through the replacement of heavy components with aluminum then in turn the cost will automatically get reduced. Nowadays the automotive manufacturers are taking a more holistic approach on the manufacturing of the most efficient, effective and eco-friendly vehicles that are helpful in serving the best for their customers.

- Safety: – With the help of aluminum the manufacturers are designing and developing the safest vehicles. Size of vehicle is safety factor. Larger vehicles are better than smaller ones in case of accidents. Aluminum reduces the vehicle weight up to 40per cent. It is also used to increase the energy absorption capacity.

- Durability: – Aluminum is naturally corrosion resistant, which helps to maintain the vehicle structure and longevity.

- Efficiency: – When the weight of the vehicle is reduced then a significant amount of fuel is saved. Reducing weight with aluminum components enables the use of smaller and efficient engines.

- Sustainability: – Aluminum is infinitely recyclable thus it can be reused and will cause no harm to our environment. It can replace any other material and increases the total life cycle of the product.

- Performance: – Aluminum’s mechanical properties enables the use of small, yet powerful and fuel efficient multi-speed transmissions. Its mechanical properties, flexibility allows to design the optimum shape components with excellent performance for each application.

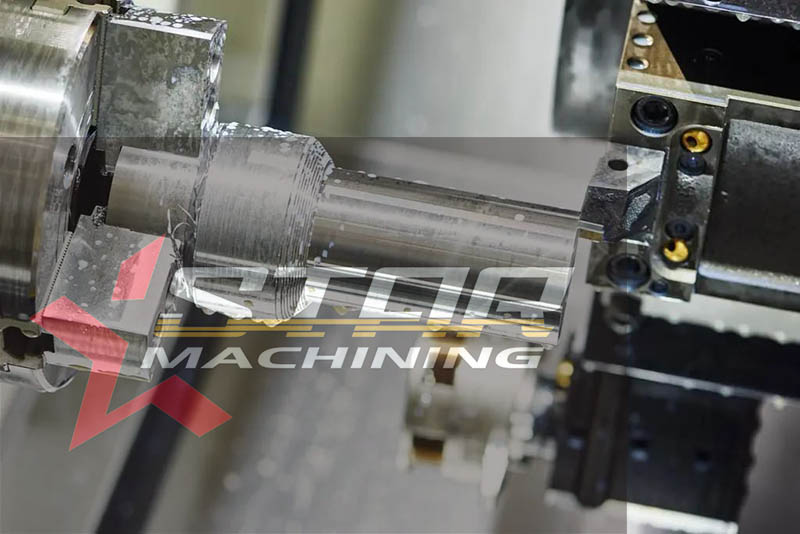

Along with the factors that we have discussed above, the important aspect is the manufacturing process of the aluminum parts. That includes what kind of design and manufacturing process we are including to manufacture the aluminum parts.

Since aluminum die casting requires tolerance, minimum draft angles, and fine lustrous surface with higher strength at the reduced cost.

Star Machining Technology is having the aluminium die casting setup of hybrid technology. That is developing hi-tech engineering projects according to the customer requirements. Star Machining holds expertise in the manufacturing of the aluminium die casting parts.

In the present era, the biggest challenge for any manufacturing company is to manufacture the goods of reduced weight. Especially for an Automobile industry weight reduction is the most important challenge as many of the key factors are considered such as fuel efficiency, performance, safety, durability, and cost. These all are the challenges that are kept under consideration. In today’s world every breakthrough innovation are is based on technology driven orientation. In such a period, the heavy components are replaced by the aluminum die casted products, i.e. from the alloy wheels to engine components. Through this article Star Machining Technology Co. Ltd., has conveyed the information about the importance and advanced features of Die Casting Aluminum parts and how rapidly these parts are replacing the heavy components with their increasing demands in market. Following are the advantages of replacing the heavy components with aluminum. It reduces the amount of generated fuel and maintenance costs thereby increasing durability. Saving weight results in saving money: – When we are talking about saving weight through the replacement of heavy components with aluminum then in turn the cost will automatically get reduced. Nowadays the automotive manufacturers are taking a more holistic approach on the manufacturing of the most efficient, effective and eco-friendly vehicles that are helpful in serving the best for their customers. Safety: – With the help of aluminum the manufacturers are designing and developing the safest vehicles. Size of vehicle is safety factor. Larger vehicles are better than smaller ones in case of accidents. Aluminum reduces the vehicle weight up to 40per cent. It is also used to increase the energy absorption capacity. Durability: – Aluminum is naturally corrosion resistant, which helps to maintain the vehicle structure and longevity. Efficiency: – When the weight of the vehicle is reduced then a significant amount of fuel is saved. Reducing weight with aluminum components enables the use of smaller and efficient engines. Sustainability: – Aluminum is infinitely recyclable thus it can be reused and will cause no harm to our environment. It can replace any other material and increases the total life cycle of the product. Performance: – Aluminum’s mechanical properties enables the use of small, yet powerful and fuel efficient multi-speed transmissions. Its mechanical properties, flexibility allows to design the optimum shape components with excellent performance for each application. Along with the factors that we have discussed above, the important aspect is the manufacturing process of the aluminum parts. That includes what kind of design and manufacturing process we are including to manufacture the aluminum parts. Since aluminum die casting requires tolerance, minimum draft angles, and fine lustrous surface with higher strength at the reduced cost. Star Machining Technology is having the aluminium die casting setup of hybrid technology. That is developing hi-tech engineering projects according to the customer requirements. Star Machining holds expertise in the manufacturing of the aluminium die casting parts.