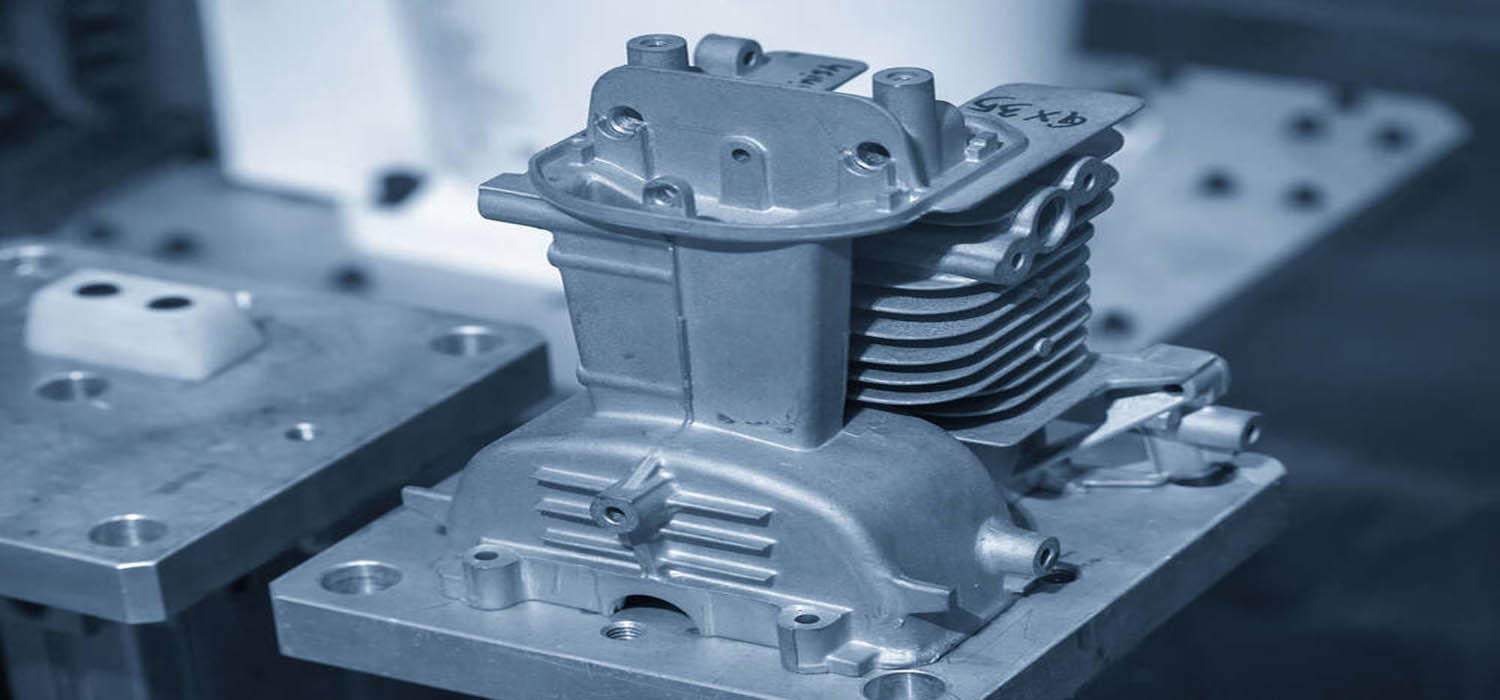

What is Die Casting

Die casting is a metal casting process characterized by the use of a mold cavity to apply high pressure to molten metal. Molds are usually machined from stronger alloys, a process somewhat similar to injection molding. Most die castings are free of iron, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and their alloys. Depending on the type of die casting, a cold chamber die casting machine or a hot chamber die casting machine is required.

Die casting is especially suitable for the manufacture of a large number of small and medium-sized castings, so die casting is the most widely used of various casting processes. Compared with other casting techniques, die casting has a flatter surface and higher dimensional consistency.

How Die Casting works

In simple terms, metal die casting works by using high pressure to force molten metal into a mold cavity, which is formed by two hardened steel dies. Once the cavity is filled, the molten metal cools and solidifies, and the dies open up so the parts can be removed. In practice, however, there are many steps in the process, and skilled engineers are required to operate die casting equipment.

Here we will divide the die casting process into three stages:

- Moldmaking

- Casting (Filling-Injection-Cavity Ejection- Shakeout)

- Post-machining

SM Tec offers full service Die-Cast solutions. Our strengths include die design and die making capabilities within SM team, melting and alloying in-house, casting, finishing, machining, and assembly.

Our manufacturing capabilities allow us to produce, finish and machine aluminum die cast components to meet a wide range of customer specifications. From simple to complex designs utilizing 380, 384 and B-390 alloys. Our expertise and experience enable us to provide close tolerances, minimum draft angles, good finish and high strength with the minimal wall thickness necessary, at the lowest cost.

We use concurrent engineering and get involved at the design phase to assure a very good PPM and cost benefit to the customer for the life of the program. The die casting process is based on rapid production that allows a high volume of die casting parts to be produced very quickly and more cost effectively than alternative die casting processes. Aluminum die casting machines last between 50,000 and 400,000 shots, depending on the application and class of the tool produced. Add these factors together and you will see why aluminum die casting has become the favored option for buyers worldwide.

As a leading high pressure aluminum die caster, each SM Tec division has expertise in producing high quality aluminum die castings requiring close tolerances, pressure tightness, good surface finish, and various secondary operations. Each SM Tec division has full access to the leading-edge resources of the combined SM corporate-wide operations. In summary, each SM division casts multiple alloys, performs many various secondary operations, and has dedicated and CNC machining centers for the parts we cast.

The Advantages of Die Casting

- Dimensional Accuracy: Die casting processes allow manufacturing of uniform and dimensionally stable parts, while maintaining the required tolerances, with higher precision than many other mass production processes.

- Outstanding properties: High durability and heat resistance of die-cast products.

- High-Speed Production allows manufacturing thousands of identical castings without the need for additional machining post finishing processes.

- Cost-effectiveness long lifespan of the tooling equipment results in the production of components with market competitive prices.

- Complex geometries: Die-casting products are stronger and lighter than comparable products manufactured with other casting methods. Moreover, die casting achieves thin and strong walls, which are not easily produced with other manufacturing technologies.

- Die-cast manufactured components result in one single part, which does not have separate welded, fastened or assembled parts, giving more strength and stability to the manufactured components.

- Die casting allows the manufacture of products with multiple finishing techniques, such as smooth or textured surfaces, which allow coating or plating without requiring complex preparations.

- Die casting technologies are able to produce components with fastening elements, bosses, tubes, holes, external threads and other geometries.

Die Casting Applications

Die casting is a powerful, versatile process suitable for a range of parts, from engine components to electronics housings. Reasons for the versatility of die casting include its large build area, range of material options, and ability to make detailed, repeatable, thin-walled parts.

- Automotive: Aluminum die casting is popular in the automotive industry as it can produce lightweight components like hydraulic cylinders, engine brackets, and gearbox cases. Zinc die casting is suitable for fuel, brake, and power steering components, while magnesium die casting works for panels and seat frames.

- Aerospace: As in the automotive industry, aerospace parts suppliers use aluminum die casting to make lightweight parts that exhibit a high level of heat and corrosion resistance. Lightweight parts reduce fuel usage.

- Energy: Die casting parts in the oil and gas sector include valves, filtration components, and impellers. Renewable energy parts like wind turbine blades can also be die cast.

- Electronics: Die casting is prevalent in electronics, as it is used for items like enclosures, housings, and connectors. Die casting parts can also be designed with incorporated heat sinks, which are necessary for many devices. Magnesium die casting is popular for thin-walled RFI EMI shielding components, while aluminum die casting for LED light components is widespread. (Die casting for LED housing typically uses an alloy like A383.)

- Construction: The construction industry uses aluminum die casting for large structures like building frames and window frames.

- Engineering: Lifting equipment, machine tools, and other equipment often contain die cast components.

- Medical: In healthcare, die casting can be used for monitoring device components, ultrasound systems, and other items.

For more information about our manufacturing capabilities and how we can help with your project, please contact us.