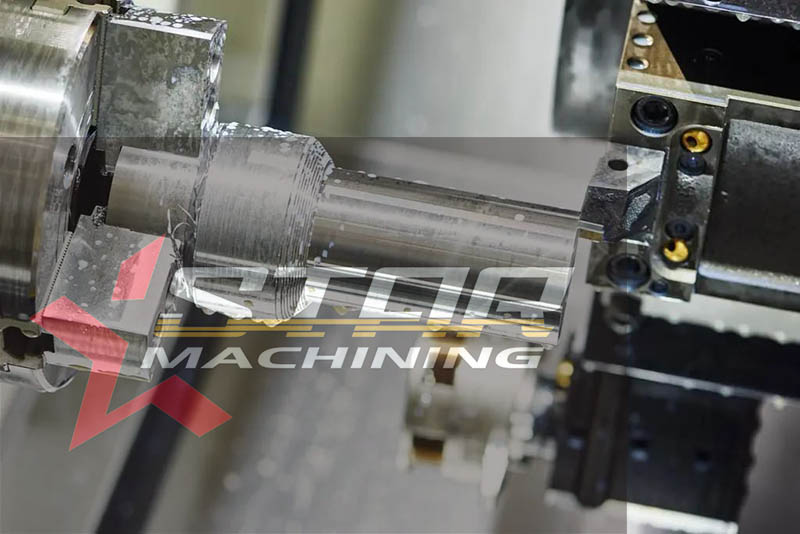

With the rapid development of science and technology and industrial economy in recent years, aluminum alloys have been widely used in aviation, aerospace, automobile, machinery manufacturing, telecommunications and medical industries, and it is the most widely used non-ferrous metal structural material in the industry. Aluminum alloys are particularly common in the machining industry. Star Machining Technology Company is a manufacturer with 15 years of experience in aluminum alloy machining.

Due to the superior mechanical properties, physical properties and corrosion resistance of aluminum alloys, it is one of the most commonly used materials for machining.

Aluminum for customers in the aerospace industry:

2000 series aluminum alloys, such as: 2024, 2A16 (LY16), 2A02 (LY6) are characterized by high hardness, of which the copper content is the highest, about 3-5%

7000 series aluminum alloys, such as: 7075, are aluminum-magnesium-zinc-copper alloys, heat-treatable alloys, super-hard aluminum alloys, with good wear resistance and good weldability.

Other common industry customers use aluminum:

5000 series aluminum alloys, such as 5052, 5083, the main element is magnesium, and the magnesium content is between 3-5%. Also known as aluminum-magnesium alloy. The main features are low density, high tensile strength, high elongation and good fatigue strength.

6000 series aluminum alloys, such as 6061, mainly contain two elements, magnesium and silicon, and are suitable for applications requiring high corrosion resistance and oxidation resistance. Good workability, easy to coat, and good workability.

Aluminum alloy machined products are widely used, such as cavity, shell, heat sink, internal small parts, etc. The engineers of Star Machining with 20 years of processing experience are very familiar with the material properties of aluminum alloys and the processing technology that needs to be used. It can also meet customer’s surface treatment requirements. If you also have the needs of aluminum alloy machining, you are right here to reach us!