In the competitive world of motorsports, every second counts. The quest for speed and performance requires precision engineering and cutting-edge technology. This is where CNC machining comes into play, revolutionizing the manufacturing process and helping the motorsports industry save time and money. Star Machining, a company that specializes in CNC machined parts for a variety of industries including the motorsports sector, understands the importance of providing high precision machined parts to meet the unique requirements of this fast paced industry.

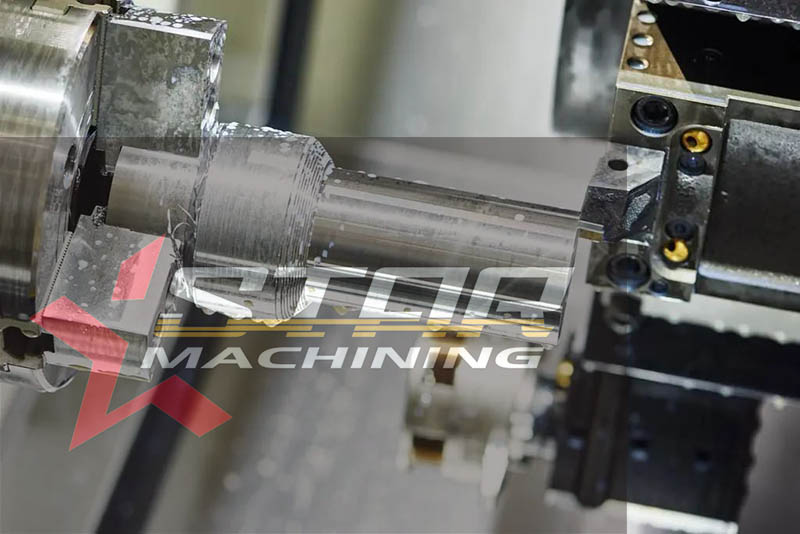

CNC machining stands for computer numerical control machining and involves the use of computer systems to control machine tools and create highly complex parts. This technology has proven to be a game-changer for the motorsports industry, enabling the production of bespoke parts with extreme precision and accuracy. By programming these machines to follow specific design instructions, manufacturers can produce race car parts tailored to meet the exact specifications of each car.

One of the significant advantages of CNC machining in the motorsports industry is the significant time savings it can provide. Traditional manufacturing methods often require extensive tool changes, manual labor, and lengthy setup times, causing significant delays in production. In contrast, CNC machining simplifies the manufacturing process by automating most tasks, eliminating the need for frequent tool changes and reducing setup times. This streamlined process allows manufacturers to produce race car components quickly and efficiently, helping them meet tight deadlines and stay ahead of the competition.

Additionally, CNC machining helps the motorsports industry save money by minimizing material waste. In traditional manufacturing methods, excess material is often wasted due to imprecise cutting techniques or human error. CNC machining, on the other hand, ensures that material waste is minimized by cutting it precisely to the desired shape and size, thereby optimizing the use of raw materials. This not only helps reduce costs, but also makes the manufacturing process more environmentally friendly.

Star Machining has consistently demonstrated its commitment to quality and customer service in the motorsports industry. They understand that delivering high-precision machined parts is critical to the success of a racing team, and that even the smallest flaw can have a major impact on performance. With expertise in CNC machining, they are able to produce parts to the industry’s exacting standards, ensuring race teams receive reliable, top-performing components.

Specialists in the CNC fabrication of racing components, Star Machining is continuously investing in upgrading its capabilities and expanding its production capacity. By staying at the forefront of technological advancements in the field of CNC machining, they are able to provide more precise and efficient solutions to their customers. Whether manufacturing lightweight components, optimizing aerodynamic designs, or producing highly heat-resistant components, Star Machining ensures that the motorsports industry benefits from the latest innovations in CNC machining.

In conclusion, CNC machining has revolutionized the manufacturing process in the motorsports industry, enabling the production of high-precision and custom parts. CNC machining helps industries save time and money with its superior time-saving capabilities and minimizing material waste. With a focus on quality and customer service, Star Machining is a leading supplier of CNC machined parts for motorsports. As they continually upgrade and expand their capabilities, they play a vital role in helping motorsports teams perform at their best and maintain a competitive edge.