The continuous growth in the field of technology and research that are exponentially changing and improving the market scenario. These upcoming researches are proved to be revolutionized for the world of metal casting. The industries are becoming more progressive, innovative, and hi-tech, challenging, and also contributing towards safety and cleanliness. The industries are improvising their work by formulating the computer based designing and simulation, energy efficiency practices, waste minimization process and the latest technologies to enhance their work ,and to degrade the level of pollution which is now an important concern for our ecosystem.

With the growing technology, new products are introducing in the market and hence the demand for the cast metal products are expected to get changed and improved in near future. Thereby it’s becoming necessary for the industries to accept the new technologies and start implementing those to fulfill the customer requirements. To develop the products with superior quality.

To design and develop the efficient cast metal products, industry will require new techniques and process that will satisfy the demands and specifications expected from the product.

It will become quiet essential for the metal casting industries to learn how to meet the demands and specifications of new products to survive in the competitive market.

Continuous new technology research in going on to improve the processes and technologies of developing metal casting products, including lost foam casting and computer based visualization tools for the casters to alternate the molding.

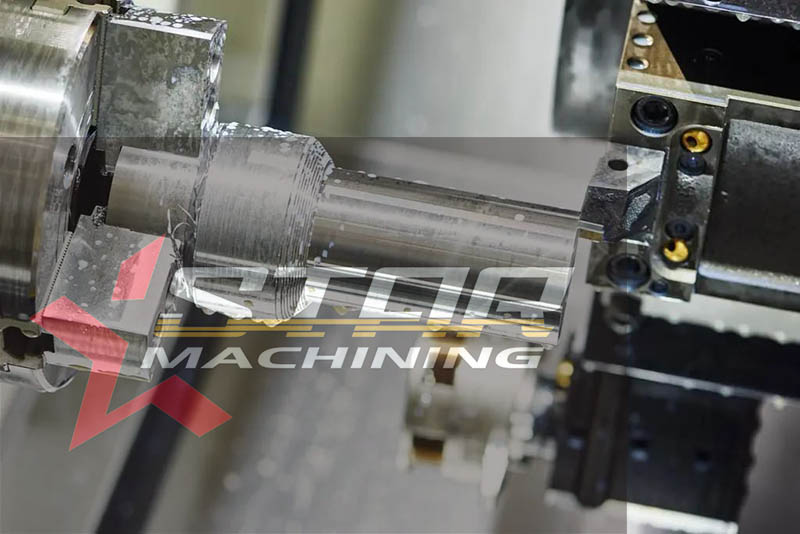

Designing is the most crucial part of die casting. For the designing of the metal casting an ideal approach is required that will include detailed study of the necessary requirements and coming up the best possible solution from it. The architectural designs, quality bench-marking and cost effectiveness considerations play an important role for the structure of metal casting.

Advantages:-

1. The above steps helps us to design the functionally stabled products with such production techniques that will cost minimum time and will serve us maximum proficient output.

2. To produce quality products which will suffer minimum number of rejections.

3.To maintain a fair balance between material and energy consumption thereby increasing the productivity at lower costs.

4. A clever designed casting requires both to be competent in the market on hand and cost effective on the other.

Several considerations must be kept while designing the framework. Thus, it will require the thorough analysis of manufacturability and production stages during the manufacturing of Die casting.

Star machining is world class supplier of excellent quality Die Casting products. We are considering concern on every step that helps us in making of quality products and improving our manufacturability. We are approaching towards the ideal framework through which we are supplying them improvised quality products, thereby fulfilling customer’s requirements.