Is it difficult to process titanium alloy? How to improve titanium processing technology? These are common problems encountered by manufacturers in industries such as aerospace and automotive, where precision and durability are critical. Titanium is a remarkable material that is highly sought after due to its incredible strength and heat-resistant properties. However, the inherent properties of titanium make it a challenging material to machine. In this article, we’ll take a closer look at specific applications of titanium machining, difficulties encountered during the process, and strategies for improvement.

Titanium is widely used for machined parts in production-intensive applications, and only the highest grades of material can withstand the heat and tension exerted on it. Its exceptional strength and high tensile strength make it ideal for critical components in aircraft engines, hydraulic systems and medical implants. Titanium allows aircraft to withstand extremely high speeds and friction, which can cause other metals such as aluminum and steel to melt. Its versatility also makes it an important material for offshore drilling equipment and parts for the automotive industry.

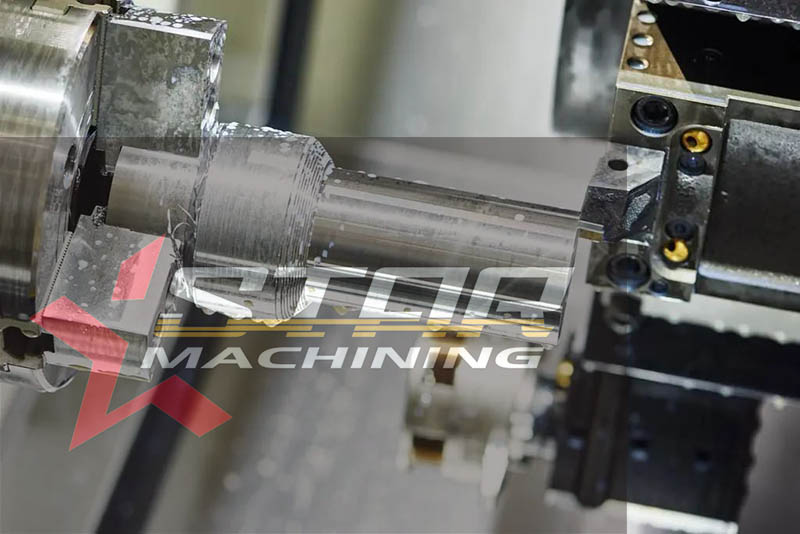

Despite its superior properties, titanium machining can be a complex and time-consuming process. One of the main challenges is its low thermal conductivity, which causes heat to accumulate in the cutting area, causing tool wear, deformation and poor surface finish. Additionally, titanium has a strong chemical affinity for cutting tools, leading to increased built-up edge and cutting forces. These factors make titanium processing more demanding than processing other materials.

To improve the titanium machining process, several strategies can be considered. First, cutting parameters such as cutting speed, feed rate and depth of cut can be precisely controlled using advanced CNC machining technology. Coupled with the use of specialized cutting tools with high wear resistance and built-up edge formation capabilities, productivity and surface finish can be significantly improved. In addition, using a cutting fluid specifically formulated for titanium machining helps dissipate heat and improve chip formation, further reducing machining difficulty.

At Dongguan Star Machining Technology Co., Ltd., we specialize in titanium processing and have extensive experience in overcoming the challenges associated with this material. Leveraging our state-of-the-art CNC machining capabilities and expertise in die-cast mold design, we have earned a reputation for delivering superior quality precision machined titanium parts. Our team of skilled engineers work closely with customers to optimize machining processes and ensure the highest standards of precision and efficiency.

In summary, titanium machining presents unique challenges due to the material’s superior properties. However, with the right tools, technology, and expertise, these difficulties can be overcome. At Dongguan Star Machining Technology Co., Ltd., we are committed to providing first-class titanium machined parts that meet the most stringent requirements. Trust us to be your reliable partner for your titanium machining processing needs.