It is simple fact that without a high level of quality, the company’s days numbered.

A manufacturing organization may looked upon as a bundle of processes which have definite inputs and outputs. The outputs from the process is in form of Product. And inputs is in the form of men, machine, materials, technology and management. The recipient of the output from the process is the customer.

“Quality is Conformance to Requirements and conformance measures the extent the products manufactured meet the design specifications”

Quality Management is the process of controlling ensuring and improving quality, both in business operations and productivity. Customer Satisfaction is the result of high Quality.

The level of quality directly impacts the amount of waste and rework a company experiences. Waste and rework increase costs and thus consume profits. Eliminating waste also has a positive effect on our environment. It takes less energy and material when quality rises. High quality needs a quality planning it involves analysis of customer needs, product and process interpretation for implementing quality control. Defect do not just happen, they are caused. There is a long list of causation pattern like marginal product design, inadequate tool maintenance, and incomplete process engineering poor vendor quality.

The quality control is one of the important function of the management. Which product are made to measures up to the specifications determined from customers’ needs and transform into the manufacturing requirements. It is concerned with making things right than rejecting those made wrong. To improve the quality which assures the products competence, it is important to implement the Quality control operational techniques and activities aimed both at monitoring a process and at eliminating causes of unsatisfactory performance.

To ensure quality of the product distinct functions are, Acceptance Function which refers to the Inspection of Product or good to ensure that they are up to the specification thereby segregate and reject those which are defective. Preventive Function refers to the identification of defects in materials, component, and machining processes. Assurance Function refers to verification that every quality characteristic or product is assured to meet a pre-determined performance standard at each stage in the manufacturing cycle.

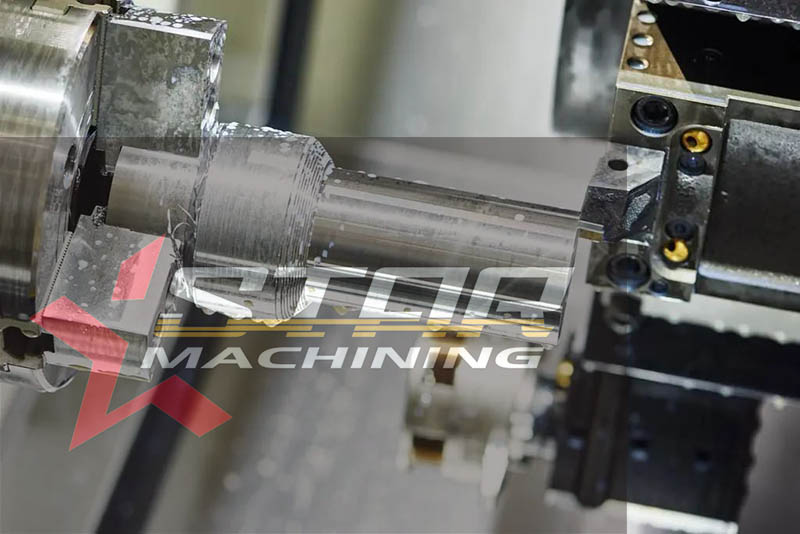

Star Machining Technology is continue to improving quality standards to achieve the Satisfaction of valuable Customers. Our aim is continues elimination of all waste in production to increase the output in lower cost with the implementation of Lean manufacturing and Just-in-Time which results Reduce manufacturing lead time, Defects and Wastage, improve labour productivity, and quality outputs. Star Machining Technology is also a Synchronous Manufacturing industry where Synchronous manufacturing applies to low Volume/high mix type of order characteristics. Where large degree of customization is required with assurance of quality.